Transformer Oil

The pulser chamber is filled with approximately 165 gallons of a medium

grade transformer oil which is stored in the reservoir of the pulser

carriage assembly when not in use. The oil is used as a dielectric to

provide the necessary high voltage insulation in the pulser chamber.

Recommended Transformer Oils:

- Tidewater Oil Company, Veedol Transformer Oil Code 2325

- Shell Oil Company, Diala Oil-A

- Texaco Oil Company, Texaco No. 55

- Gulf Oil Company, Gulf Paramount No. 33

- Esso Oil Company, Esso Univolt No. 33

- It is imperative that the transformer oil be maintained at a

high electrical strength, with either replacement or purification whenever

contamination is suspected. It is recommended that periodic dielectric

strength measurments be performed according to the ASTM test designation

D877-49. (See "ASTM Standards on Electrical Insulating Liquids and Gases"

published by the American Society for Testing Materials.)

Oil Installation

In order to load the oil from the reservoir in the pulser carriage to the

pulser chamber:

- Check that the drain valve lever on the pulser carriage is still in the

OPEN position (shut down position).

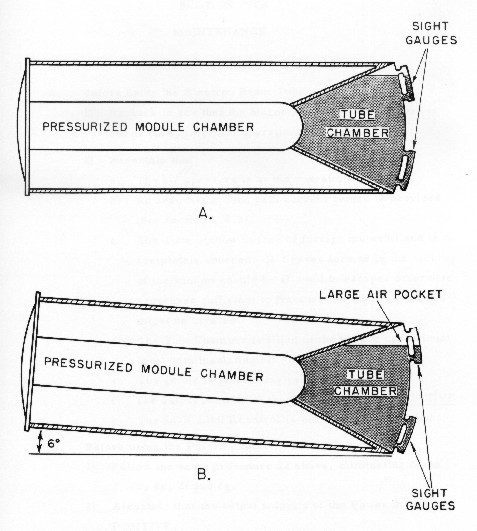

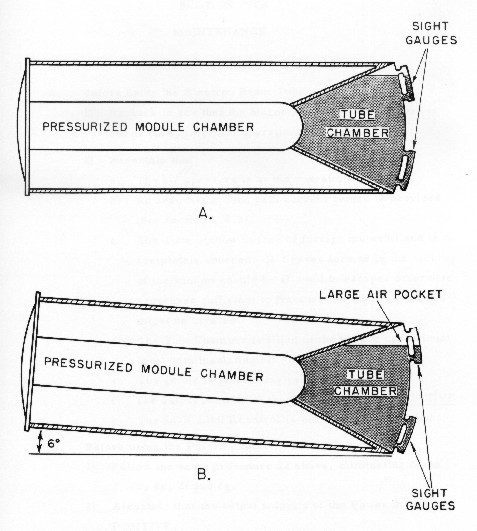

- It is imperative that the pulser be level during the filling process, or

too large an air pocket may result. Such a condition is conducive to damaging

high voltage arcing inside the tube chamber. Refer to the diagram above.

- Activate the switch on the pulser carriage to turn the oil pump ON.

- Monitor oil level until it appears at the line behind the top sight

glass. (Approximately 2 minutes, 35 seconds.)

Carefully watch the sight gauges during oil loading. Prepare

to shut off the pump as soon as oil can be seen in the lower sight gauge.

Failure to do so may will cause the operator to be sprayed with transformer

oil when the safety pressure release valves are tripped.

When the proper oil level is reached, place the drain valve lever in

the CLOSED position and turn the oil pump OFF.

Back to Operational Instructions page

Back to Homepage